Escalators in railway stations are critical components of modern transportation infrastructure, facilitating the smooth and safe movement of large volumes of passengers between platforms, concourses, and exits. Ensuring high reliability is essential, as any downtime can cause significant delays and congestion, affecting both commuter experience and operational efficiency. Companies like IFE, with over 30 years of experience in lift and escalator design, manufacturing, and maintenance, emphasize engineering solutions that comply with Australian standards and international safety regulations. These measures ensure that railway station escalators maintain optimal performance, even under heavy, continuous use.

Ensuring the reliability of railway station escalator requires a combination of design, installation, and ongoing maintenance strategies. Modern escalators incorporate durable materials, robust motor systems, and precision engineering to withstand high passenger traffic. Regular inspections, timely lubrication, and component replacements are vital to preventing unexpected failures. IFE implements intelligent monitoring systems in its escalators, enabling real-time diagnostics and proactive maintenance. This approach minimizes downtime, extends the operational life of the escalators, and guarantees consistent safety and performance for passengers in busy railway stations.

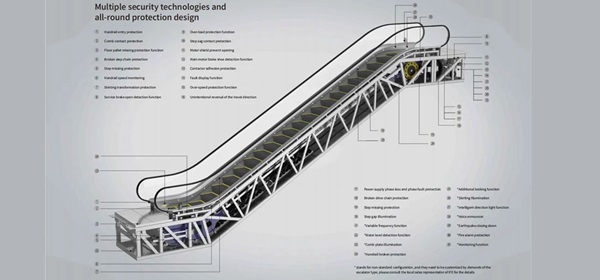

Beyond mechanical durability, reliability is enhanced through advanced safety and operational features. Step-level sensors, emergency stop buttons, anti-slip treads, and automatic speed adjustments all contribute to reducing wear and tear while protecting passengers. Noise reduction mechanisms and vibration dampers improve user comfort and reduce stress on mechanical components. IFE’s railway station escalators integrate these features, combining high-quality engineering with practical safety solutions to ensure that the escalator remains both efficient and dependable, even during peak hours.

Different maintenance strategies can significantly affect the reliability and lifespan of railway station escalators.

Aspect | Reactive Maintenance | Preventive & Predictive Maintenance |

Approach | Fix problems after they occur | Regular inspections and early issue detection |

Downtime | High, unexpected interruptions | Minimal, scheduled and planned |

Component Lifespan | Reduced due to wear and delayed repairs | Extended due to timely interventions |

Safety Risk | Higher, failures may endanger passengers | Lower, potential hazards detected early |

Cost Efficiency | Short-term savings, long-term higher costs | Optimized, reduces emergency repair expenses |

This comparison highlights why adopting preventive and predictive maintenance strategies is essential for railway station escalators, allowing operators to ensure continuous reliability and a superior passenger experience. IFE’s integrated monitoring solutions support this proactive approach, providing data-driven insights for maintenance planning.

Reliable escalators improve overall station efficiency, reduce operational disruptions, and enhance commuter satisfaction. High-performance railway station escalators also support the longevity of the station’s infrastructure by reducing mechanical stress and component wear. Implementing intelligent monitoring, advanced safety features, and proactive maintenance ensures that escalators remain operational even under heavy daily loads. With global experience in over 50 countries, IFE demonstrates how engineering excellence and continuous innovation can deliver railway station escalators that are safe, efficient, and highly reliable for the long term.